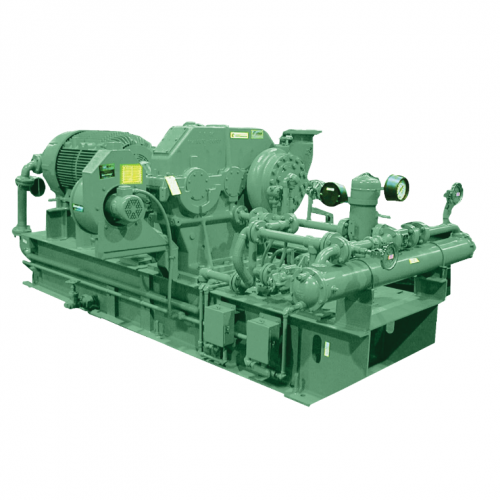

MSG® TURBO-AIR® COOLED 2000 Centrifugal Air Compressor

The MSG TURBO-AIR COOLED 2000 is a great match for almost any location and conditions. The air-cooled design eliminates the installation restrictions and the utility costs associated with water-cooled units by removing the cost of pumping and treating water, and maintaining the water system.

特性

RELIABLE CENTRIFUGAL COMPRESSOR – NOW AVAILABLE AIR COOLED

The MSG TURBO-AIR COOLED 2000 centrifugal compressor is designed for applications where there is a limited supply or no water available for cooling.

The MSG TURBO-AIR COOLED compressor makes it possible for more industries around the world to enjoy all the advantages of our state-of-the-art centrifugal compressor design.

ISO CERTIFIED CLASS 0

The MSG TURBO-AIR centrifugal compressor product line has been engineered to produce oil-free air for more than 60 years. This certification officially acknowledges the ability of our compressors to produce 100% oil-free air, providing our customers with enhanced quality assurance.

Additional Resources

Operating Comparison: Air vs. Water Cooled

BENEFITS OF MSG TURBO-AIR COMPRESSORS:

ISO 8573-1 Certified Oil-Free Air

Prevents oil contamination of your system

Limits the potential for compressed air pipeline fires caused by oil carryover

Eliminates costly waste disposal problems associated with oil-laden condensate

Eliminates the expense and associated maintenance requirements of oil-removal filters, since no oil enters the compressed air stream in the compressor

Simple Installation

True unloading capability helps to take advantage of opportunities for energy savings

Increased uptime compared to alternative technologies translates into reduced operating life-cycle costs

Reduced number of external connections

Compact design reduces required floor space

Meets OSHA’s sound level requirements without sound enclosure

Low-Cost Operation

True unloading capability helps to take advantage of opportunities for energy savings

Increased uptime compared to alternative technologies translates into reduced operating life-cycle costs

Excellent part-load efficiencies for any operating load

No sliding or rubbing parts in the compression process causing wear or efficiency loss

Easy Operation

The MAESTRO™ Universal control panel provides a built-in web server, allowing compressor monitoring using your local intranet

Significant annual savings in operating cost by providing more precise control

Easy-to-use, automatic operation

Easy Maintenance

Compression elements do not wear or require periodic replacement

No oil-removal filters to clean or replace

Accessible, horizontally split gearbox for quick inspection

Intercooler and aftercooler bundles are easy to remove for inspection and cleaning

Water-in-tube design intercooler and aftercooler allow for simple mechanical cleaning

Maintenance-free dry coupling

High Reliablity

Thrust loads absorbed at low speed

Non-contacting air and oil seals

Stainless steel compression elements

Conservative, high-quality gear design

Extended life pinion bearing design

Centrifugal compressors are proven to have a long mean time between failures (MTBF), and independent research has shown an industry-leading availability of 99.7%

MSG TURBO-AIR COOLED 2000 CENTRIFUGAL COMPRESSORS 3-STAGE COMPRESSOR LAYOUT

1. Oil Cooler: Air-cooled heat exchanger for lubrication system

2. Aftercooler: Air-cooled heat exchanger for 3rd stage discharge air

3. 2nd Stage Intercooler: Air-cooled heat exchanger for 2nd stage discharge air

4. 1st Stage Intercooler: Air-cooled heat exchanger for 1st stage discharge air

5. Fan Plenum & Cooler Fan: Fan and plenum to facilitate air-cooled heat transfer

6. Inlet Filter: Removes airborne particulate prior to 1st compression stage

7. 3rd Stage of Compression: Final compression stage to reach pressure set point

8. 2nd Stage of Compression: Intermediary compression stage before final compression

stage

9. 1st Stage of Compression: Initial compression stage of atmospheric air

10. Control Center: Single-point electrical connection for MAESTRO Universal control panel,

drive motor starter, and auxiliaries

11. Sound Enclosure: Enclosure provides quiet operation at 85 dBA

12. Compressor Discharge: Discharge from final compression stage to aftercooler and subsequent downstream equipment

![]() SPECIFICATIONS

SPECIFICATIONS

FILTER BY

SPECIFICATION | METRIC | IMPERIAL |

Standard Input Power | 93-260kw | 125-350hp |

Discharge Pressure | 3.5-10.3 barg | 50-150psig |

Inelt Flow | 15-50m3/m | 500-1800cfm |

Weight | 5543 kg | 12000lb |

SPECIFICATION | ||

Standard Input Power | 93-260kw | 125-350hp |

Discharge Pressure | 3.5-10.3 barg | 50-150psig |

Inelt Flow | 15-50m3/m | 500-1800cfm |

Weight | 5543 kg | 12000lb |

你可能还喜欢

MSG® TURBO-AIR® 2000 离心空压机

MSG® TURBO-AIR® COOLED 2000 Centrifugal Air Compressor

TURBO DryPak™ 离心空压机和 HOC 干燥机套装

MSG® Centac® C400 离心空压机

MSG® TURBO-AIR® 2040 离心空压机

URBO-GAS 2040 Centrifugal Compressor

MSG® Centac® C700 离心空压机

MSG® TURBO-AIR® 3000 离心空压机

MSG® Centac® C800 Centrifugal Air Compressor

MSG® 2/3 离心式空气和气体压缩机